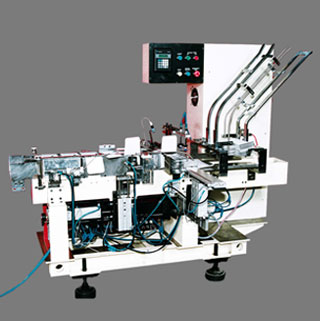

BOSS Boxing System for Strips

Efficient and Precise Boxing Solution for Pharmaceutical Strips

Product Overview

The BOSS Boxing System for Strips is a highly efficient and precise packaging solution designed specifically for pharmaceutical strips such as blister packs. This system automates the process of collating and boxing strips, ensuring consistent quality and high-speed operation. With its robust construction and user-friendly design, the BOSS system meets the rigorous demands of the pharmaceutical industry while maintaining strict quality control.

Applications

- Packaging of pharmaceutical blister packs for tablets and capsules.

- Boxing other lightweight, flat-packed products such as confectionery or healthcare items.

Key Features

- High-Speed Operation: Automates boxing for increased throughput, minimizing manual intervention.

- Strip Collation: Collects and arranges strips in the desired orientation and count for efficient boxing.

- Precise Boxing Mechanism: Ensures each strip is placed securely and neatly into the box.

- Material Compatibility: Handles a variety of box types and sizes for versatile applications.

- Durable Design: Engineered for long-term reliability and minimal maintenance.

- Compact Footprint: Saves space on the production floor while delivering maximum efficiency.

Benefits

- Increased Productivity: Automates boxing processes, reducing labor costs and increasing output.

- Consistent Quality: Maintains uniform placement and secure boxing for professional-grade packaging.

- Operational Flexibility: Accommodates various strip sizes and box dimensions.

- Cost-Effective Solution: Optimized for minimal waste and energy consumption.

Technical Specifications

| Specification | Details |

|---|---|

| Output Capacity | High-speed boxing for pharmaceutical strips |

| Box Dimensions | Adjustable to accommodate different box sizes |

| Strip Sizes Supported | Configurable for varying strip lengths and widths |

| Material Compatibility | Cardboard, lightweight packaging materials |

| Electrical Supply | 415 V, 3-phase, 50 Hz |

| Power Consumption | Compact, with customizable dimensions |

| Machine Weight | Approximately 1,500 kg |

Use Cases

- Pharmaceutical Blister Pack Boxing: Ideal for securely boxing tablet and capsule strips for retail and bulk distribution.

- Healthcare Products: Packaging healthcare items like diagnostic kits and test strips.

- Confectionery Products: Boxing flat items such as small chocolate or candy packs.

- Specialty Packaging: Custom boxing needs for lightweight and flat-packed products.

Accessories and Add-Ons

- Box Feeder Module: Automates box loading for uninterrupted operation.

- Inspection System: Ensures accuracy in strip collation and box filling.

- Spare Parts Kit: Includes essential components for routine maintenance and quick replacements.

Maintenance and Support

- Maintenance Schedule: Regular servicing recommended every 1,200 operational hours for peak performance.

- Warranty: Comprehensive 1-year warranty covering parts and labor.

- Support Services: 24/7 technical assistance and on-site maintenance available globally.

Success Stories

Testimonials

The MK8D has greatly enhanced our overall production efficiency. Its consistent performance, simple operation, and dependability have made a remarkable difference in our daily manufacturing process.

Jane Smith

Operations Manager at Silverline Tobacco WorksThe MK8SM fits perfectly into our mid-scale operations. Its compact structure, reliable performance, and smooth functionality have significantly improved our production efficiency and consistency.

John Doe

Production Manager at TruLeaf Tobacco Pvt. Ltd.The MK9 has completely transformed our production process with exceptional speed, precision, and reliability, enabling us to meet growing demand efficiently while maintaining superior quality output.

Sarah Lee

Operations Director at Regent Tobacco IndustriesThe PM4 Plug Making Machine has optimized our rod production with exceptional precision, impressive speed, and reliable consistency, becoming an essential part of our manufacturing line.

Mark Anderson

Operations Manager at Vertex Tobacco Manufacturing Co.The HLP2 has exceeded our expectations by delivering excellent packaging speed, reliability, and consistent product quality, helping us maintain productivity and efficiency throughout operations.

Emma Carter

Packaging Manager at Crystal Leaf Tobacco Corp.The HLP1 perfectly fits our medium-scale production. Its compact structure, high reliability, and efficiency have significantly improved our operational performance and product consistency.

Rajesh Kumar

Owner of Bluecrest Tobacco CompanyThe PA 7RO has simplified our filter assembly process with its precise, high-speed operation, becoming an indispensable component of our efficient production workflow.

Ahmed Khan

Production Manager at Amberline Tobacco WorksThe M2 10 Duplex has strengthened our packaging line by offering reliable, fast, and consistent performance, helping us meet rising production targets without compromising quality.

James Smith

Production Manager at NovaTobac IndustriesThe WRAPID-350 has greatly improved our packaging efficiency. Its precision, speed, and easy operation have helped us meet growing market demands seamlessly.

Rahul Sharma

Operations Manager at Sterling Goods Pvt. Ltd.The GPW III has enhanced our packaging process with superior efficiency, accuracy, and speed, helping us achieve higher productivity and improved product quality consistently.

Ankit Mehra

Packaging Manager at GreenEdge EnterprisesThe GPW-III(S) is reliable, efficient, and versatile, enabling us to package diverse products easily while maintaining superior quality and consistent output standards.

Emily Davis

Packaging Manager at PrimeFlex Packaging Pvt. Ltd.The COPAR Bundling Machine has boosted our packaging performance through unmatched speed, precision, and flexibility, making it an integral part of our production system.

Sunil Verma

Packaging Supervisor at ApexPack SolutionsThe CW 11 has upgraded our packaging operations by providing consistent accuracy, reliability, and excellent speed, resulting in improved productivity and better output quality.

Priya Das

Operations Manager at ModernEdge Packaging Co.The CM-60 has elevated our cartoning efficiency with excellent accuracy, reliability, and performance, ensuring top-quality results and consistent production standards.

Aditya Sharma

Packaging Head at SuperiorPack Industries Pvt. Ltd.The FW 200S offers outstanding versatility and precision, delivering reliable performance and excellent speed, perfectly suited for our medium-scale packaging requirements.

Kavita Mehra

Packaging Manager at BrightLine Packaging WorksThe SWIFT-VX has dramatically improved our detergent soap packaging process, providing unmatched speed, consistency, and reliability that have significantly enhanced overall productivity.

Ramesh Patel

Operations Manager at AquaPure Soaps Ltd.The TSW 160 has been a game-changer for our soap wrapping line, delivering exceptional speed, accuracy, and reliability in every production cycle.

Meera Shah

Production Manager at GlowWave Soaps Pvt. Ltd.The ACM-XFH 1050 has optimized our capsule production process with impressive precision, speed, and efficiency, allowing us to handle higher output without quality compromise.

Arun Prakash

Director at MedCura Pharmaceuticals Ltd.The BOSS system has transformed our strip boxing process through efficient performance, reliability, and compliance, maintaining productivity while meeting stringent packaging standards.

Priya Nair

Packaging Head at VitaCore Pharma Pvt. Ltd.

Request a Quote

Contact us today to learn how the BOSS can enhance your production capabilities.

Explore Products

Access detailed specifications and features by downloading our product brochure. Download Brochure

Have questions? Reach out to our experts for personalized assistance. Contact Us